Your flooring is a fundamental aspect of your home or business space, and it’s essential that it remains in excellent condition to ensure safety and aesthetics. However, various challenges can plague your floors, especially when dealing with concrete surfaces.

At Floor Shield, some common questions we get are “What is efflorescence and spalling?” and “Does efflorescence and spalling lead to cracking and coating failure?”

We’ll additionally be tackling the slipperiness of sealed and polished concrete surfaces that can pose safety hazards. Plus, how good preparation work goes a long way in ensuring a stable and long-lasting concrete coating.

HOW DO YOU TREAT EFFLORESCENCE IN CONCRETE?

Efflorescence is a pesky problem that can mar the appearance of your concrete floors. It occurs when moisture seeps through the concrete, depositing salts and minerals on the surface. A certain amount of efflorescence is typical for uncoated concrete, but when it becomes severe, it signals excessive moisture within the concrete.

Excess moisture can lead to significant issues, including coating delamination. Floor Shield tackles high-moisture concrete by following a meticulous process:

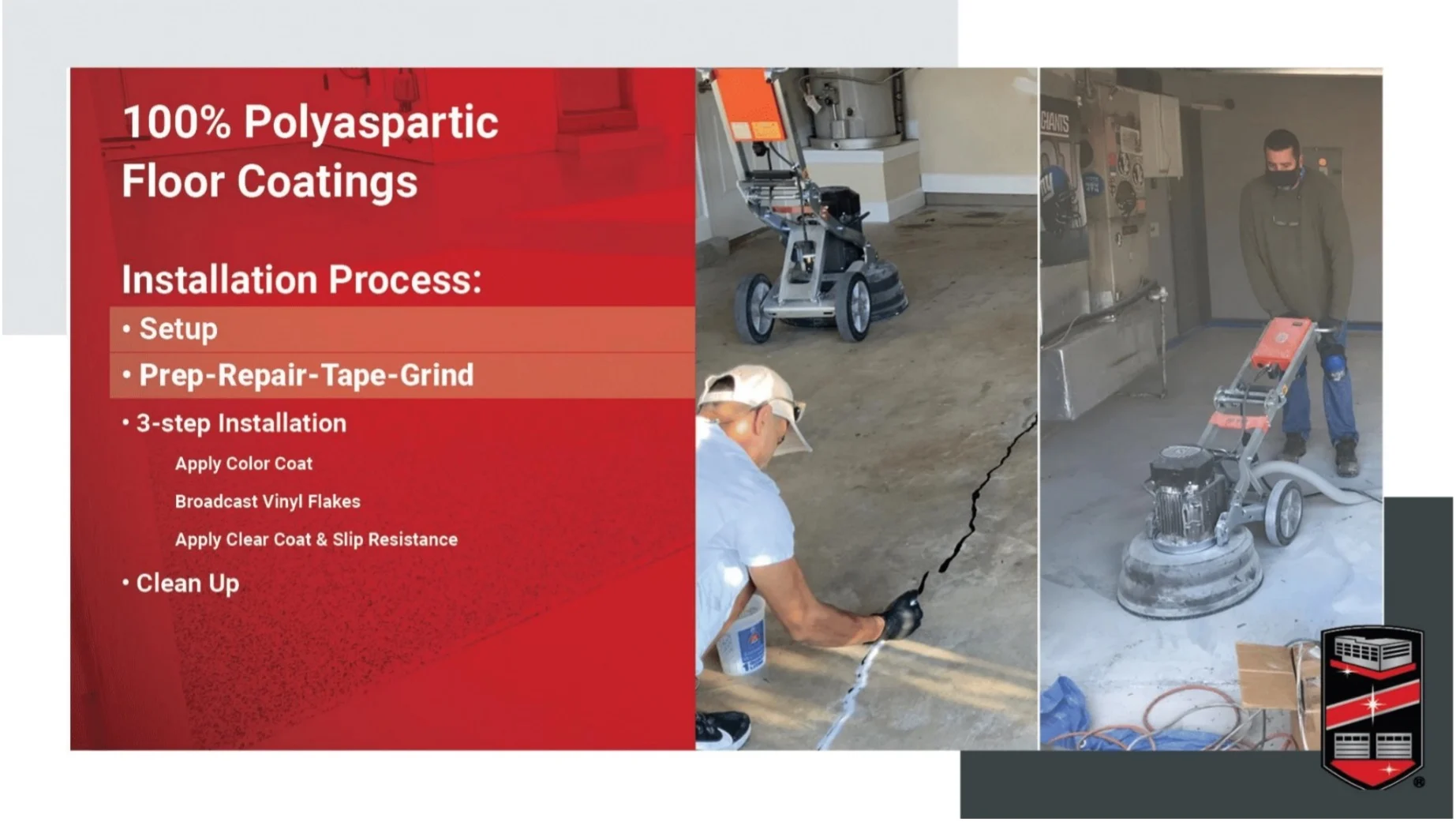

- First, we grind the floor down to get a smooth profile on the surface for better adhesion.

- Then, we apply a moisture vapor barrier and allow it to dry for about a day. This barrier prevents moisture from interfering with the coating’s adherence to the concrete.

- On the occasions the job calls for it, we will put a color coat over the Floor Shield Moisture Vapor Epoxy if it will be exposed to UV light.

- Finally, our polyaspartic topcoat is applied to seal and protect the floor.

Floor Shield always utilizes a moisture meter to assess the amount of water present in the concrete. If the moisture level exceeds 6%, a moisture vapor barrier is added to mitigate potential problems.

Another reason for coating failure is inadequate preparation. Acid etching, a common but less precise method of surface preparation, can result in an uneven surface that hinders proper coating adhesion.

In contrast, Floor Shield opts for grinding the concrete, effectively removing dirt and dust particles, and creating an ideal surface for the coating to adhere to. This also removes the top layer of concrete that may contain contaminants, which we’ll delve into more below.

HOW DO YOU FIX CONCRETE SPALLING?

Spalling is another issue that often plagues concrete floors. It refers to the deterioration of the top layer of concrete, which creates an uneven and difficult surface profile for coatings to adhere to. This not only compromises the aesthetic appeal but also affects the longevity of your flooring solution.

To resolve spalling problems, Floor Shield takes a comprehensive approach:

- First, we grind the floor to remove the deteriorating surface.

- Then, we apply a leveling compound to ensure a smooth and even surface.

- After leveling, we grind the floor once more to create an optimal surface for our coating to bond with. The coating not only seals the surface against dust and particles but also protects the concrete from future water-related damage.

This thorough process ensures that your concrete floor is not only visually appealing but will also stand the test of time.

CONCRETE CRACKING TYPES

Concrete cracking is a common issue, often resulting from natural movements of the earth. There are four main types of cracks in concrete:

- Hairline cracks: These are minor and typically don’t affect the floor’s structural integrity.

- Shrinkage cracks: These occur during the concrete curing process as the material shrinks, causing tiny cracks.

- Movement cracks: These are more substantial and usually result from significant shifts in the Earth’s surface.

- Structural cracks: These are the most severe and can expose the rebar within the concrete, causing structural failure.

Exposed rebar is a significant concern as it’s a sign of concrete breakdown and failure. Rebar, the metal poles within the concrete, are the concrete’s support and provide additional flexibility.

When rebar is exposed to moisture and air and begins to rust, it can lead to severe concrete damage that oftentimes escalates into entire sections of concrete breaking off from the floor’s surface.

Floor Shield will patch any crack bigger than a hairline before applying our product. Our polyaspartic coating is flexible and moves with the shifting substrate, preventing new cracks from showing up on the surface of your floor.

ARE CONCRETE COATINGS SLIPPERY?

Sealed and polished concrete can be incredibly slick when wet. This is especially problematic for outdoor areas like back patios and driveways, where safety is a priority. To address this concern, many outdoor surfaces are “broom-finished,” which adds significant texture to prevent slips. However, this kind of texturing isn’t very suitable for garage floors, where aesthetics are more important.

Floor Shield has a best-of-both-worlds solution by designing our product with coated concrete surfaces in mind. Our coatings include silica, a robust aggregate that adds texture to a flat surface.

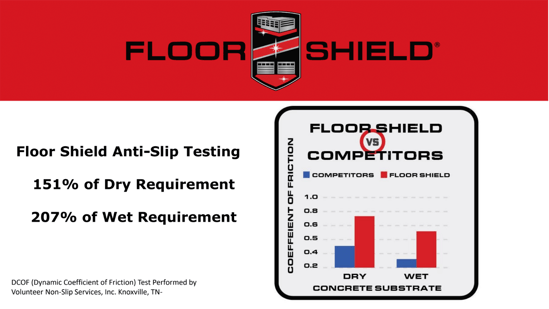

We provide the necessary friction to meet OSHA requirements for public areas. In fact, our product exceeds industry standards, with a coefficient of friction testing at 151% of the dry requirement and 207% of the wet requirement. This added slip resistance ensures the safety of those walking on the coated surface.

HOW DO YOU PREVENT FREEZE THAW IN CONCRETE?

In regions with colder climates, the freeze-thaw cycle is a major concern for concrete. Concrete is naturally porous, so when it becomes wet and then experiences temperature drops, the water within it can freeze and expand, leading to significant damage from within.

In extreme cases, this process can cause concrete to break apart, exposing the rebar and potentially leading to structural failure. To mitigate this issue, northern regions often use harder concrete, which has smaller pore sizes and is less susceptible to water infiltration. This doesn’t prevent water from still seeping in and causing damage, though.

Floor Shield Coatings provide an effective solution to this problem. When applied to a concrete surface, Floor Shield bonds with the concrete, creating a waterproof barrier that fills up the concrete’s pores, inhibiting the absorption of moisture.

WHY DOES MY CONCRETE LOOK SO DIRTY?

Bare, porous concrete is more susceptible to moisture-prone bio-growth, such as:

- Algae

- Mold

- Lichen

This will pollute your floor’s aesthetic appeal and make it very unsanitary. A coated floor acts as a barrier against moisture and provides a smooth surface for easy clean-up.

Another negative of bare concrete’s porous nature is its propensity to stain. Floor Shield seals and blocks these pores with the added benefit of being a stain-resistant product.

WHY YOU SHOULD COAT YOUR CONCRETE FLOOR

Concrete floors are prone to various issues, from moisture-related problems like efflorescence to structural concerns such as:

- Spalling

- Cracking

- Freeze-thaw damage

Floor Shield Coatings offer a comprehensive solution to these problems by providing effective:

- Moisture control

- Surface preparation

- A shield against the elements.

If you’re interested in addressing these common floor issues with a concrete coating, you can scroll down to get a free, no-obligation quote.